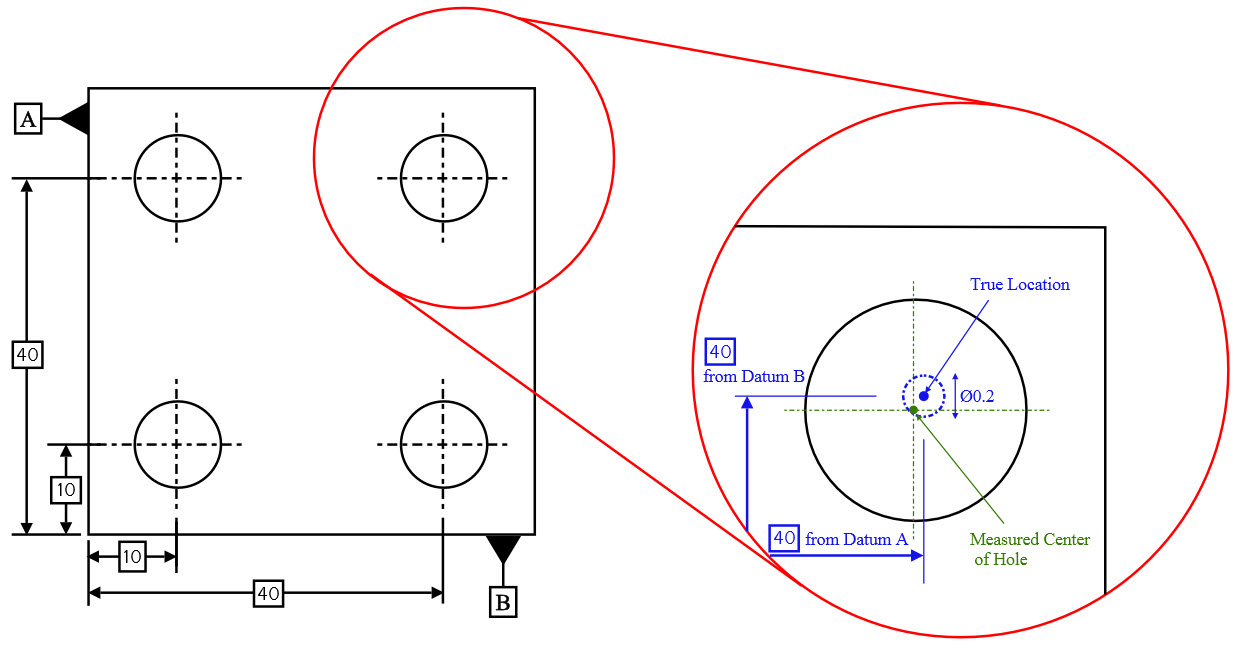

True position calculation in CMM software Written by Ray Xing True position is probably one of the most used tolerance tools in any CMM software and depending on which industry you're in, you've probably used this tool on every program that you've created for so many years. Manual Calculation Of True Position Tolerance 7,2/10 349 reviews A result (also called upshot) is the final consequence of a sequence of actions or events expressed qualitatively or quantitatively. Possible results include. Online true position calculator MMC to find the tolerance deficit value and true position based on offset (X), offset (Y) and specified true position value. In electrical engineering design, GD&T position is a versatile tolerance to have control over location, coaxially, axis offset of any part feature.

This paper focuses on process capability evaluation method for position tolerance under maximum material condition. Picbasic serial communication. Due to application of maximum material condition the position tolerance specification varies individually for each part, the approach of percentage normalization is introduced to calculate position process capability index. Bush is taken as an example, and true position percentage normalization of 30 parts are calculated.

Considering the true position constitution relative to position tolerance at maximum material condition, related individual percentages are used to express the result and the same tolerance size 100% is obtained as for a unilateral tolerance. Process Capability index is calculated with Minitab software.

Manual Calculation Of True Position Formula Conversion Chart

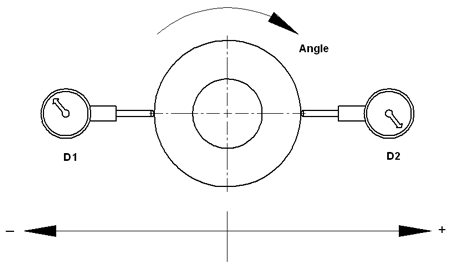

Hi,Because your formula gives the 2D deviation as the shortest distance between actual and nominal position of an element.In GD&T - that's the philosophy or let's just say definition of GD&T - the tolerance is defined by the diameter which the actual position produces, if the nominal position is the center of that diameter. And because the designer took the diameter and not the radius, you have to take the shortest distance times two.Are you OK now or are you doubting because of the 10 microns?peter.